A mobile crusher is a portable crushing and screening system used to process hard materials such as stone, rock, concrete, and asphalt on-site. It is typically mounted on wheels or tracks and allows for easy transportation between construction or mining sites.

The operation starts with raw material being fed into a hopper, then directed to a crusher (jaw, impact, or cone). The crushed material is then screened by vibrating screens and transferred by conveyors. This system is highly efficient for temporary jobs or dynamic work environments.

Applications:

Road, railway, airport construction

Recycling of demolition materials

Aggregate production

Dam construction

Open-pit mining

What Is a Stationary Crusher, What Is It Used For, How Does It Work, and Where Is It Applied?

A stationary crusher is a fixed crushing and screening facility designed for continuous, high-volume production. These systems are permanently installed in quarries or mining fields and involve heavy-duty machinery.

It includes primary, secondary, and tertiary crushers, feeders, vibrating screens, and conveyors. The system is configured to handle large quantities of materials over long periods.

Applications:

Quarry operations

Cement and concrete production

Mining and mineral processing

Large infrastructure projects

Differences Between Mobile and Stationary Crushers

Mobility: Mobile crushers are transportable; stationary ones are fixed.

Setup Time: Mobile crushers are quicker to deploy.

Capacity: Stationary systems offer higher throughput.

Investment Purpose: Mobile units suit short-term needs; stationary units are for long-term use.

Maintenance: Mobile crushers allow easier access but may wear faster.

What Are 19-21% Manganese Blow Bars, What Are They Used For, How Do They Work, and Where Are They Applied?

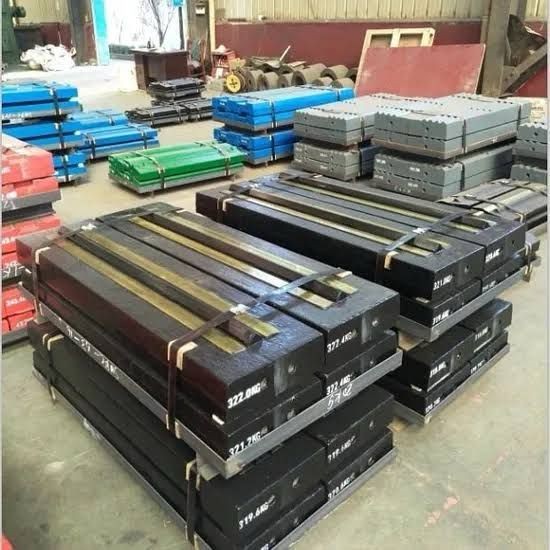

Crusher blow bars are key impact crusher parts. Those made from 19-21% manganese steel are exceptionally durable and suitable for high-impact crushing applications. Manganese gives the steel the ability to work-harden under stress, increasing its resistance to wear.

These bars are mounted on the rotor of the crusher. As the rotor spins, the blow bars strike incoming material and crush it. Their ability to endure heat, friction, and repeated impacts is critical in mining and recycling operations.

Applications:

Aggregate crushing

Mining operations

Concrete and asphalt recycling

Cement plants

English

English

Le français

Le français

Türkçe

Türkçe